Revolutionary IoT-Based Smart Pump Monitoring

KRYFS Technologies offers a next-generation IoT-based Pump Monitoring Solution that provides real-time performance insights to enhance reliability, efficiency, and energy savings. Designed for critical sectors like water, manufacturing, HVAC, and oil & gas, this smart IoT power monitoring system uses predictive analytics to prevent failures, reduce downtime, and optimize pump performance.

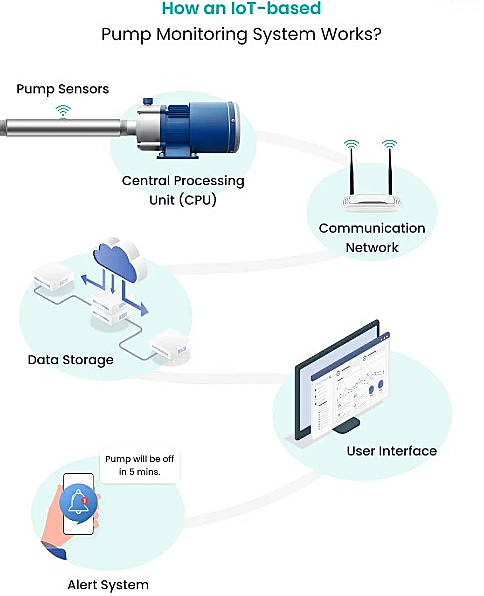

Comprehensive System Architecture

Our state-of-the-art IoT pump monitoring solution integrates seamlessly with your existing infrastructure, providing unprecedented visibility into pump performance, health, and operational metrics.

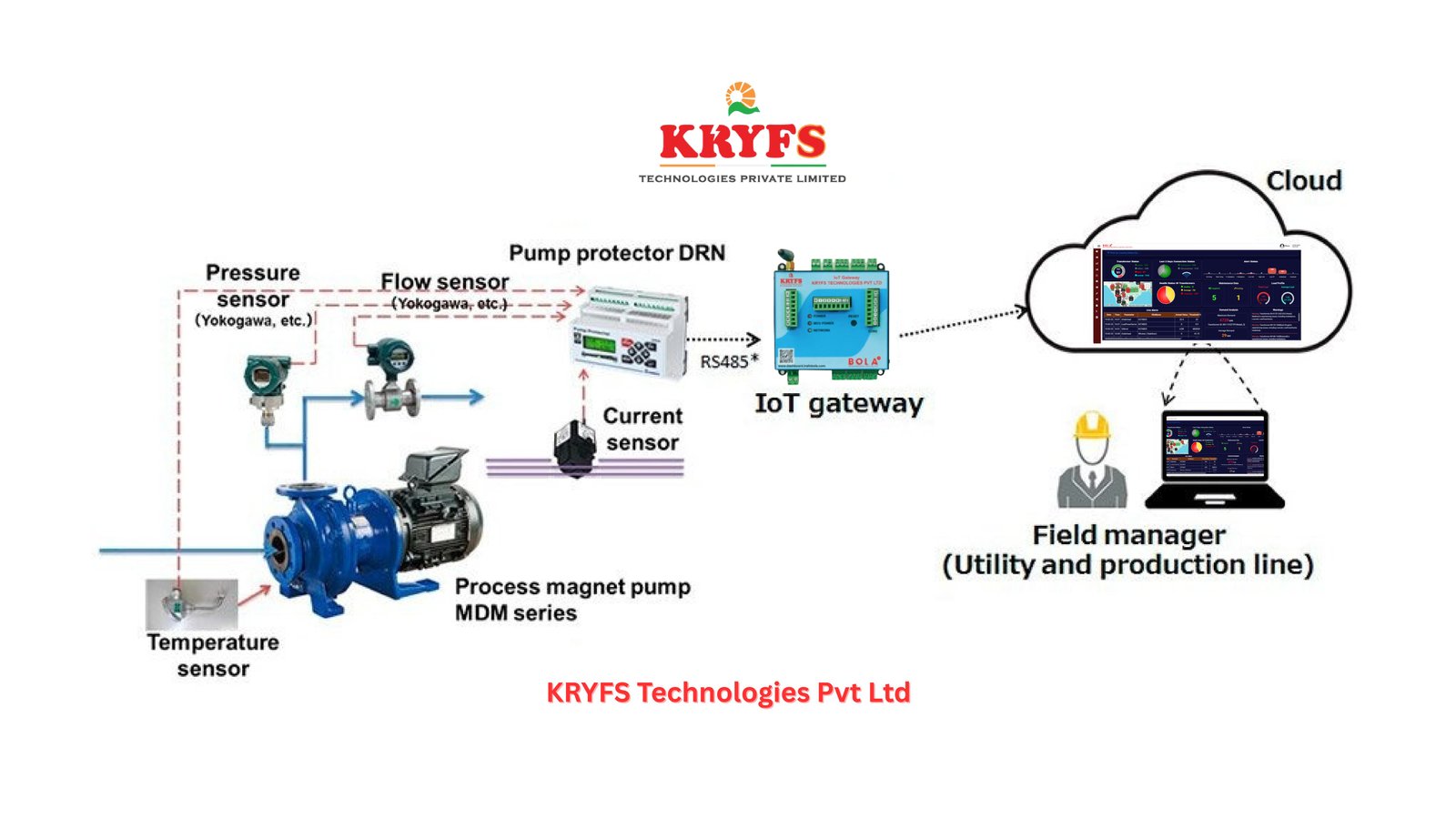

Industrial IoT Architecture Integration

Our solution leverages proven industrial protocols and architectures, ensuring seamless integration with existing SCADA systems and enterprise infrastructure.

Multi-Sensor Array

Flow, pressure, temperature, vibration, and current monitoring with 0.1% accuracy

Industrial Gateways

RS485-based Modbus modules supporting redundant communication paths

Cloud Analytics

Real-time processing, machine learning, and predictive algorithms

Role-Based Access

Customized dashboards for operators, engineers, and management

% Downtime Reduction

% Energy Savings

% System Reliability

Months ROI Period

Comprehensive Benefits & ROI

Predictive Maintenance

Advanced machine learning algorithms analyze historical patterns and real-time data to predict failures 2-4 weeks in advance, enabling scheduled maintenance during planned downtime.

- Vibration analysis

- Thermal monitoring

- Performance trending

Energy Optimization

Real-time IoT power monitoring and intelligent load balancing help reduce energy costs by up to 45% without compromising performance.

- Power factor analysis

- Load optimization

- Efficiency tracking

Intelligent Alerts

Multi-level alert system with customizable thresholds sends immediate notifications via SMS, email, and push notifications with detailed diagnostic information.

- Priority classification

- Escalation protocols

- Mobile integration

Advanced Analytics

Comprehensive data visualization with customizable dashboards, trend analysis, and performance benchmarking for data-driven decision making.

- Real-time dashboards

- Historical analysis

- Custom reports

Enhanced Security

Enterprise-grade cybersecurity with encrypted data transmission, secure authentication, and compliance with industrial security standards.

- End-to-end encryption

- Multi-factor authentication

- Audit trails

Seamless Integration

Compatible with existing SCADA systems, PLCs, and enterprise software through standard industrial protocols and APIs.

- Modbus

- REST API access

- Legacy system compatibility

Technical Specifications

Sensor Specifications

- Temperature Range: -40°C to +150°C (±0.1°C accuracy)

- Pressure Range: 0-1000 PSI (±0.25% accuracy)

- Flow Rate: 0.1-10,000 LPM (±1% accuracy)

- Vibration: 0.1-1000 Hz frequency range

- Current: 4-20mA, 0-5A measurement range

Communication Protocols

- Wired: RS485, Modbus RTU/TCP, Ethernet

- Wireless: WiFi,Gsm/GPRS/4G LTE

- Protocol: Modbus TCP IP, IEC104, MQTTS, HTTPS

- Cloud: AWS, RESTful APIs

- Security: TLS 1.3, AES-256 encryption

Ready to Transform Your Pump Operations?

Empower your facility with KRYFS Smart Pump Monitoring Solution. The future of IoT power monitoring and predictive maintenance