DG Monitoring & Performance Optimization

Did you know that unmonitored DG sets can waste up to 25% of fuel and experience 40% more unplanned downtime?

-

Real-time electrical parameter monitoring helps optimize fuel consumption and reduces operational costs by identifying inefficiencies in power generation and load management.

-

IoT-based DG monitoring with Multi-Function Meters (MFM) provides continuous visibility into voltage, current, power factor, and energy consumption patterns across all phases.

-

KRYFS Technologies' DG monitoring solution delivers actionable insights through cloud dashboards, enabling data-driven decisions for better generator performance and maintenance scheduling.

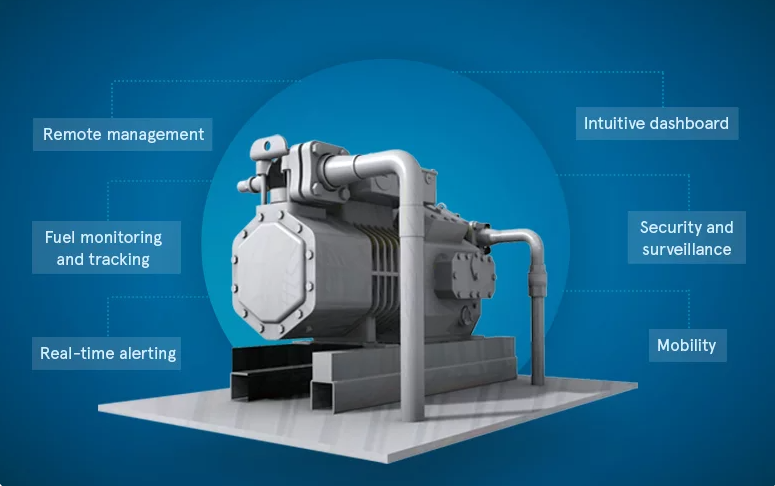

DGMS – Diesel Generator Monitoring System

IoT-Enabled Solution

KRYFS Technologies offers an IoT-enabled DG Monitoring solution focused exclusively on real-time electrical parameter monitoring of Diesel Generators. With seamless integration using Multi-Function Meters (MFM) and RS485 (Modbus RTU) communication, this solution empowers users with live visibility into generator performance—right from their dashboards.

What We Monitor?

Voltage

R-Y-B Phase & Line-Neutral

Current

R-Y-B Phase

Power

Active, Reactive, Apparent

Power Factor & Frequency

Real-time monitoring

Energy Consumption

kWh and kVAh

Harmonics

Optional based on MFM

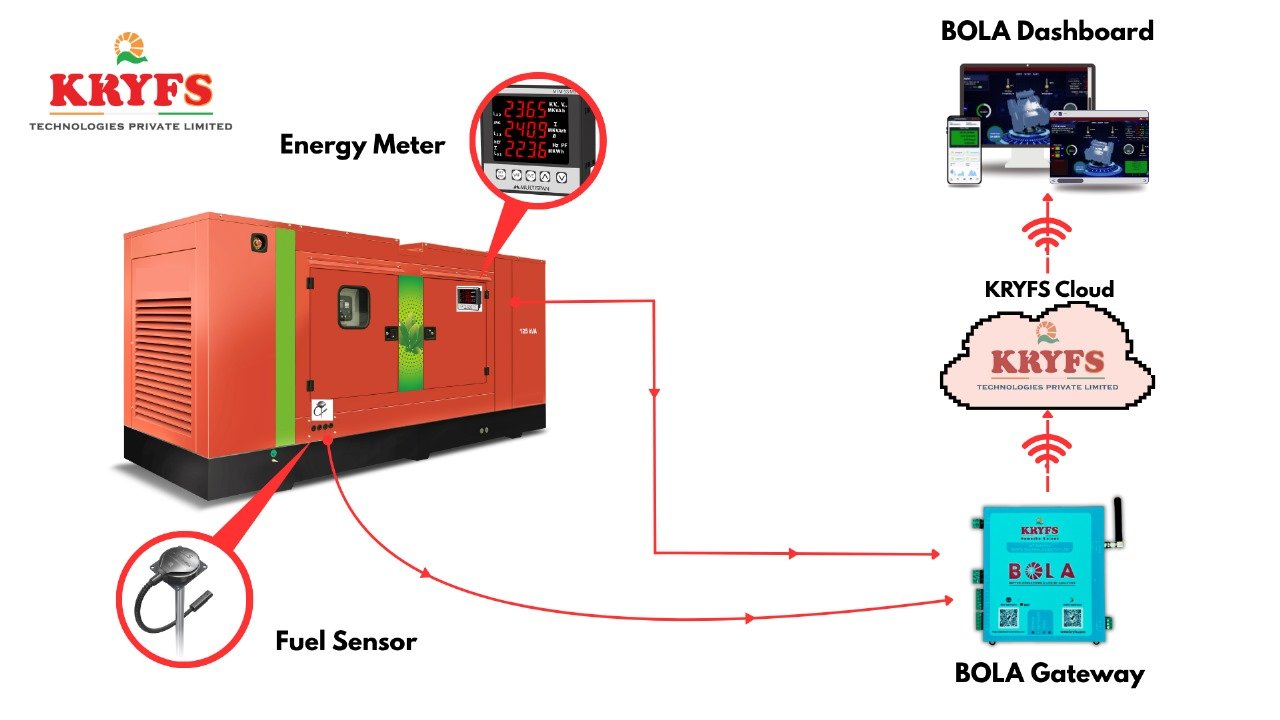

Smart IoT-Based Diesel Generator Monitoring System Complete Architecture Overview

IoT Sensors & MFM

Data Collection

BOLA Gateway

Data Transmission

AWS Cloud

Data Processing

Dashboard

Analytics & Insights

Sensors & Energy Meters Integrated with IoT Gateway

Captures critical DG parameters like fuel level, runtime, voltage, current, power, and temperature using sensors and Multi-Function Meters (MFM), all connected via MODBUS/RS485 to the BOLA IoT Gateway.

BOLA IoT Gateway

Collects and transmits real-time data from both energy meters and sensors to the cloud, enabling 24/7 generator performance monitoring, control, and alerts.

KRYFS Cloud Platform

Robust AWS-based cloud infrastructure for secure storage, real-time analytics, and high availability of DG data with 99.9% uptime.

BOLA Dashboard Access

User-friendly web and mobile dashboards to monitor generator health, electrical load, fuel consumption, runtime, and maintenance alerts—anytime, anywhere.

DG Monitoring System Features

Real-Time Data Acquisition

Continuous reading of electrical parameters via MFM using RS485 communication.

Cloud Dashboard Access

View generator performance remotely via our web-based dashboard with intuitive charts, logs, and visualizations.

Data Logging & Reports

Access historical trends, download logs, and generate reports for energy analysis and audits.

Alert Configuration

Set thresholds for overvoltage, undervoltage, current imbalance, or power factor dips and get notified instantly.

Multi-Location Support

Monitor multiple DGs across various locations from a single centralized dashboard.

Top Benefits of IoT-Based DG Monitoring

Real-Time Monitoring

Track generator performance and faults instantly from any location.

Reduced Downtime

Receive alerts for critical issues to prevent unexpected breakdowns.

Data Analytics

Access historical trends and generate reports for audits and optimization.

Remote Control

Start, stop, and manage DG operations remotely via cloud dashboard.

Enhanced Security

Secure communication with TLS encryption and user authentication.

Battery Health Monitoring

Monitor battery voltage, temperature, and status in real-time.

Smart DG Insights

Our IoT-based DGMS combines transformer condition monitoring with electrical data analytics to improve generator utilization, reduce fuel wastage, and maintain balanced load distribution.

The system continuously analyzes voltage fluctuations, current imbalance, and power factor deviations to detect early warning signs. With customizable alert thresholds and historical trend analysis, you can implement preventive maintenance, reduce operating costs, and extend the generator’s lifespan.

By integrating IoT transformer asset management with remote DG monitoring, KRYFS enables industries to achieve a new level of efficiency, reliability, and control in power management.

Copyright © kryfstech.com All Right Reserved.