CASE STUDY 1

Basic information

View

Customer Name

Utility board in south of India.

Transformer Rating:

63 KVA.

BOLA Installed Date

31 Oct 2020.

Problem Detected Date

30 Nov 2020.

Problem Identified

View

1.Real Time Notification

The board authorities were swiftly notified by the BOLA device, which delivered real-time alerts indicating deviations in both oil temperature and overload, enabling them to promptly address potential issues and maintain optimal operational conditions.

2. Temperature Increased

In the comprehensive case study, it was determined that the transformer's operational parameters were closely monitored, revealing a crucial finding: the maximum oil temperature reached 72 degrees Celsius

Root Cause Analysis

View

1. Transformer Overloading

Throughout a specific month, the transformer consistently operated under a load exceeding 120% of its rated capacity, signaling a sustained period of elevated demand and prompting a closer examination of its performance under challenging conditions.

2. Electricity Theftning

Situated in a distant location, the transformer has encountered frequent instances of electricity theft, a trend that hasn't gone unnoticed by utility managers who've been able to identify and address these incidents through the BOLA device—an innovative Internet of Things (IoT) solution.

Potential Solutions Recommended

View

1. Data-Driven Recommendations

The KRYFS team, Proposes a strategic approach. Their data-driven analysis suggests a proactive measure to prevent transformer overloading by maintaining the load consistently below 80% of the maximum rated load.

2. Performance Optimization

The recommended strategy emphasizes optimizing performance. Avoiding overloading not only preserves operational efficiency but also extends the transformer's lifespan, ensuring sustained reliability and minimizing potential issues.

Result

View

1. Transformative Efficiency

Based on KRYFS team recommendations and ongoing monitoring by the BOLA device, the utility board officials maintained the loading of the transformer below 80% and as a result, maximum oil temperature were monitored below 50 degree.

1. Cost Saving

Premature failure due to excessive heating and insulation is thus avoided. As a result, the life of the transformer increased by about 5 years and saves repair and maintenance cost approximately of Rs 60K.

Recognized by DPIIT as a Startup under the IoT sector.

VIEWOur Solutions

We Provide Best Industrial Solutions

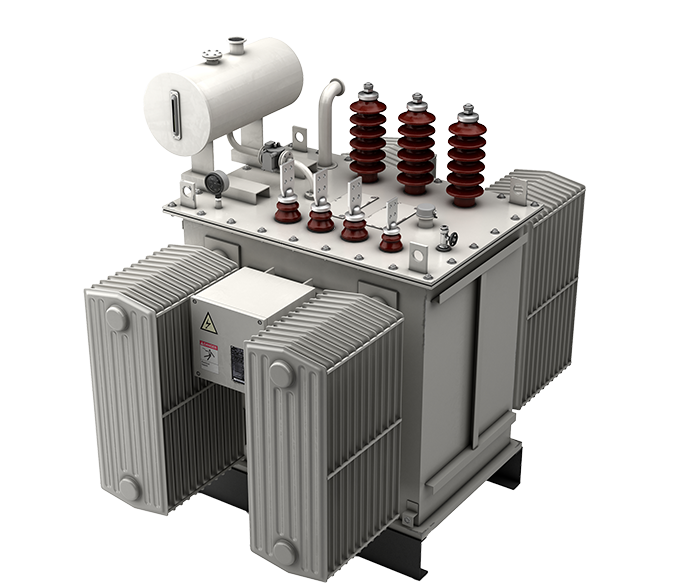

Distribution & Power Transformer Monitoring System (DTMS & PTMS)

BOLA device provides complete IoT-based transformer monitoring for power and distribution assets. The BOLA Dashboard delivers advanced analytics for performance optimization and real-time transformer monitoring IoT insights.

Renewable energy Monitoring(SOLAR & WIND)

BOLA extends its IoT platform for solar and wind energy monitoring, offering real-time data tracking and historical analysis to improve renewable system performance.

Energy Management, Analysis and Recommendation System (EMARS)

A comprehensive IoT power monitoring solution that displays factory-installed energy meters on one dashboard in real time enabling smarter energy use, reduced costs, and predictive maintenance.

Instant Alerts for Real-Time Anomalies

BOLA’s remote transformer monitoring system delivers instant alerts and real-time diagnostics for preventive maintenance. When parameters exceed set thresholds, automatic notifications via email and SMS ensure quick responses. With multi-user notification, up to five team members receive instant alerts. Access your system securely from anywhere enabling remote monitoring of distribution transformers with no limit on user logins. BOLA focuses purely on transformer condition monitoring, giving you control over actions while providing real-time insights.

Clients

Customer who trust us

We’re proud to collaborate with industry leaders across multiple sectors.

Testimonial

What Our Clients Say!

"We are completely satisfied with the performance of your BOLA Device which you have installed on our two power transformer of 20MVA at our Bidadi Industrial Area, Karnataka factory. This device has helped us to monitor our transformer in a much better way."

Toyota Tsusho India Pvt. Ltd.

“KRYFS’s installation and remote transformer monitoring device have performed exceptionally well with consistent IoT-based insights.”

Torrent Power Ltd.

"KRYFS Technologies Pvt Ltd. supplied 07 BOLA devices and a gateway with remote monitoring software, which have been functioning well in our network for about a year. The devices provide a user-friendly interface, email alerts for abnormalities, and detailed monthly reports, proving effective for asset monitoring and preventing sudden breakdowns."

Tata Power Company Limited.

“The BOLA system provides seamless real-time transformer monitoring with SMS and email alerts for our 315kVA DTR operating reliably since installation.”

West Bengal State Electricity Distribution Company Limited.

"We are completely satisfied with the performance of your BOLA Device which you have installed on our distribution transformer of 2000KVA at our Dadra factory. This device has helped us to monitor our transformer in a much better way."

G R PET PREFORMS

"The dashboard for the remote monitoring is giving the great insight of our power consumption data helping us to save enrgy usage. Also trends and curves are easy to understand and analyze."

AL-CAN EXPORTS PVT. LTD.

"A committed partner in our journey of business excellence, mutual growth, and continuous improvement."

Atul Ltd.

Transform Your Business with Real-Time Insights

"Gain a competitive edge with BOLA the IoT-based distribution transformer monitoring system built for predictive maintenance and optimized energy management. Achieve smarter, safer, and more efficient operations with IoT transformer asset management and real-time transformer health analytics from KRYFS Technologies."

Copyright © kryfstech.com All Right Reserved.